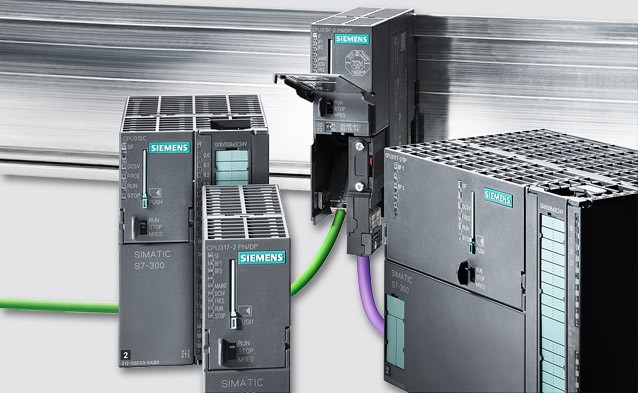

Simatic S7 - 1500

Key Features:

• Modular, scalable, and universally usable system in IP20 level of protection

• The system solution for a variety of automation applications in discrete automation

• Highest performance with excellent usability

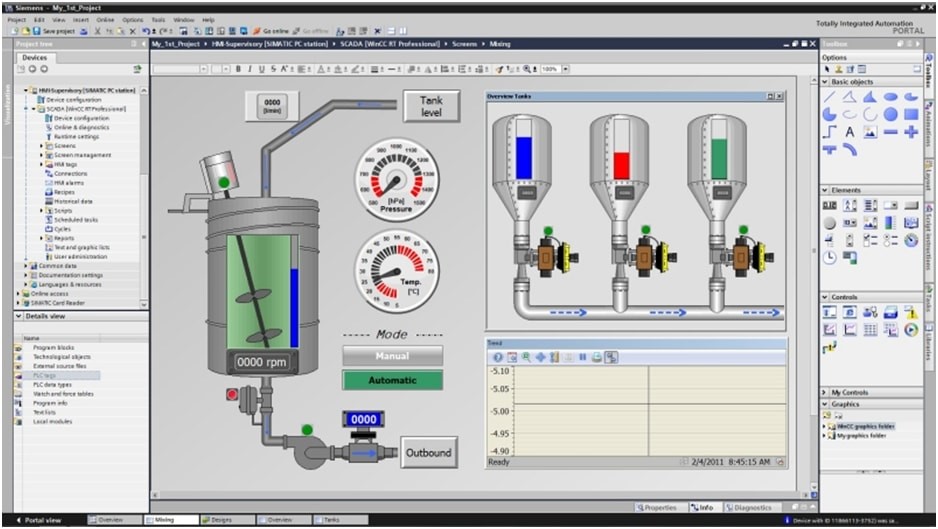

• Configurable exclusively in the Totally Integrated Automation

Portal with STEP 7 Professional V12

Performance

• Performance increase through

– Faster command execution

– Language extensions

– New data types

– Faster backplane bus

– Optimized code generation

• Powerful communication:

– PROFINET IO (2-port switch) as standard interface

– Optional additional PROFINET interface, e.g. for network separation

– Expandable with communication modules for bus systems and point-to-point connection

Integrated technology

• Motion Control integrated without additional modules:

– Standardized blocks (PLCopen) for connection of analog and PROFIdrive-capable drives

– The Motion Control functionality supports speed-controlled and positioning axes as well as external encoders

• Comprehensive trace functions for all CPU variables for real-time diagnosis and sporadic error detection; for effective commissioning and quick optimization of drives and controls

• Comprehensive control functionalities: e.g. easily configurable blocks for automatic optimization of the control parameters for optimum control quality

• Additional functions through available technology modules: e.g. high-speed counting, position detection, or measurement functions for signals up to 1 MHz

Security Integrated

• Password-based know-how protection against unauthorized reading and modification of program blocks

• Copy protection for greater protection against unauthorized copying of program blocks:

With copy protection, individual blocks on the SIMATIC memory card can be tied to its serial number so that the block can only be run if the configured memory card is inserted into the CPU.

• Rights concept with four different authorization levels:

Different access rights can be assigned to various user groups. The new protection level 4 makes it possible to also restrict communication to HMI devices.

• Improved manipulation protection: Changed or unauthorized transfers of engineering data are detected by the controller.

• For use of an Ethernet CP (CP 1543-1):

– Additional access protection by means of a firewall

– Setup of secure VPN connections (V12 SP1 or higher)

Design and handling

• CPUs with display for plain text information:

– Information about order numbers, firmware version, and the serial number of all connected modules can be displayed

– Setting the IP address of the CPU and additional network settings directly on site, without programming device

– Display of occurring error messages directly as plain text message, meaning reduction in downtime

• Uniform front connectors for all modules and integrated potential bridges for flexible potential group formation simplify stock keeping and reduce wiring costs

• Integrated DIN rail in the S7-1500 mounting rail: quick and easy installation of additional components such as miniature circuit breakers, relays, etc.

• Central expansion with signal modules: for flexible adaptation to any application

• System cabling for digital signal modules: for fast and clearly arranged connecting to sensors and actuators in the field and simple wiring inside the control cabinet

• Power supply:

– Load current supply modules (power modules) to supply the module with 24 V

– Power supply modules to supply power to the internal module electronics via the backplane bus

• Distributed expansion:

– Use of up to 30 signal modules, communication modules, and technology modules via the PROFINET interface module IM 155-5 for the ET 200MP I/O system

– No difference in terms of handling and system functions in central and distributed operation

Integrated system diagnostics

• Integrated system diagnostics for CPUs, activated by default:

– Consistent plain text display of system diagnostic information in the display, TIA Portal, HMI, and web server, even for drive messages. Messages are updated even if the CPU is in STOP state.

– System diagnostics integrated in the CPU firmware. Configuration by user not required. The diagnostics is automatically updated on configuration changes.

CPU Variants:

• CPU 1511-1 PN

• CPU 1513-1 PN

• CPU 1516-3 PN/DP